Full Description

The industry-leading moisture/density sorter groups green lumber into four categories, each with similar drying characteristics to help realize kiln productivity improvements and a reduction in the standard deviation after drying. Employing high-speed temperature and distance sensors, the system applies algorithms to maintain sorting through all conditions. Proprietary background suppressions means sensor calibration is not required. Intuitive software shows sorting results and the number of boards in each group to better coordinate drying scheduling.

Features

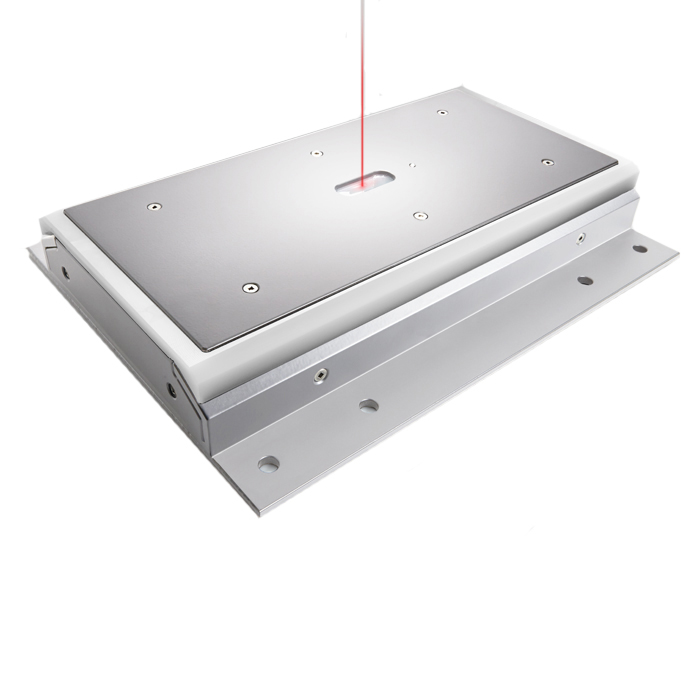

- Non-contact, moisture/density sawmill meter for sorting green lumber before kiln drying

- Digital pulse capacitive technology takes multiple readings per board and reports average or peak

- Laser distance sensors compensate for vertical board movement or warp as the

board passes over the sensors

- Optional high-speed temperature sensor and reference sorting parameters

- Proprietary background suppression eliminates sensor drift; sensor calibration

not required

- Assigns a ‘dry-ability’ index number (DIN)

for sorting into four groups and the optional paint system marks each board for easy visual identification

Benefits

- Increases kiln productivity by up to 15% and decreases moisture content variation after drying up to 2%

- Maintains consistent sorting year-round – even with frozen wood

- Capable of measuring boards at up to 250 lugs/min and passing sort decision to PLC

- Painted loads allow for optimal kiln charges to be built by fork lift operators

- Software monitors production for daily shift reports and allows access to historical data

- Non-contact sensors minimize maintenance requirements and maximizes up-time

Key Specifications

- Sensor Width: Plate 7″ – Mounting Frame 12″

- Sensor Length: 16″ & 22″ Standard, 12″ to 30″ lengths available

- Number of Sensors: Scalable

- Sensor Location: 1″ – 2″ below lumber, non-contact

- Line Speed: Max 250 lugs/min

- Operating Temperature: -5ºC to +40ºC

- Moisture Content Range: 6-100%

Cart

Cart ☰ Menu

☰ Menu

by Webolutions

by Webolutions