☰ Menu

☰ Menu

Technology continues to transform lumber manufacturing with a focus on process improvement – saving time, enhancing quality, and increasing profit.

With ProTrac Kiln Performance Software from Finna Sensors, lumber producers can now maximize profitability using the industry’s smartest software solution that helps track and control moisture content — and product quality — from sawmill to planer.

ProTrac connects one or more advanced Finna Sensors devices to help mill operators quickly identify what’s going right or what’s going wrong, up-stream in the drying process through the planer. It’s smart software that provides the industry’s most advanced run reports for process control and quality analysis.

With the control of ProTrac, mills can now review moisture at a given point in the drying process and look upstream, based on historical data collected, to find places for improvements in achieving standard deviation expectations in moisture content. That translates to less waste and better grade recovery.

Using ProTrac data-driven reports, mills have accurate and necessary information to achieve accountability and consistency across the entire production line. Now the guesswork is out of the equation, and operators have the data-driven confidence to make lower risk changes in the process that achieve more desired outcomes.

Moisture content affects cost and profit in many ways. Ensuring increased profitability in modern lumber operations is best driven by tracking and understanding moisture content from end-to-end of production.

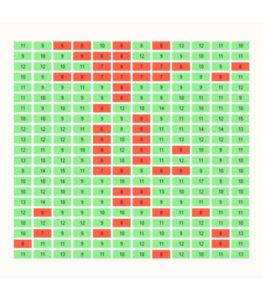

If lumber is too wet, or too dry, when it reaches the planer, ProTrac’s deep and detailed reporting, can help operators analyze the root cause of these process issues. Based on ProTrac’s robust data captured in the planer by Finna Sensors’ Transverse Moisture Planer System, ProTrac lets operators dig into the critical problems and quickly find solutions that work.

ProTrac reports can even help operators identify mechanical issues and problems like poor air flow, fan issues, and stuck valves.

Mills that maximize the value of ProTrac are achieving next level integration, data mapping, analysis, and process improvements. A key feature includes utilizing the power of package tracking through bar code generation, application, and scanning.

Bar code integration enables continuous real time tracking from the sawmill to planer. This ensures operators drill down into the most robust package data to solve issues at the individual board level.

ProTrac also collects inputs from other Finna Sensors hardware integrations, including both KilnScout-Wireless (for continuous) and KilnScout-Wired (for batch) in-kiln moisture systems, to automatically populate ProTrac in real time.

With this added information-rich data from additional points in the manufacturing process, operators can easily run reports that help them find specific and detailed solutions to their wet/dry concerns — from seasonality to package spacing to charge cycle times — to the entirely unexpected.

If you’re drying lumber in today’s market with Finna Sensors systems, it’s an easy answer — ProTrac is right for your operation. These data-driven decision options can drive your profitability higher.

With its suite of smart software features, ProTrac benefits your operation with enhanced performance and improved efficiency. Data reports can help you find savings on throughput, fuel costs, start up times, waste, grade recovery, and more.

In successful lumber productions, ProTrac Data Analysis Software is designed to meet the increasing demands on mill operators, and easily integrates with existing Finna Sensors moisture devices.

Together, these products deliver the information you need to make better process decisions, dramatically reduce operator feedback time, improve drying times, support increased grade recovery, and work quickly to improve your profitability.

Reach out to us today so we can discuss increasing throughput and profitability through use of ProTrac software.